News

News

- What are the advantages of evaporative air coolers?

- Closed cooling tower winter operation need to pay attention to what?

- How to choose the right closed cooling tower?

- What is the difference between an air cooler and a water cooler

- What are the factors affecting condensation heat transfer

Contact Us

E-mail:shengbaofrp@gmail.com

Mobile:+86 15253666158

Tel:+86-0536-4736888

Address:West Shou, Jinshan Street, Xin'an Street, Anqiu City, Weifang City, Shandong Province

Technical information

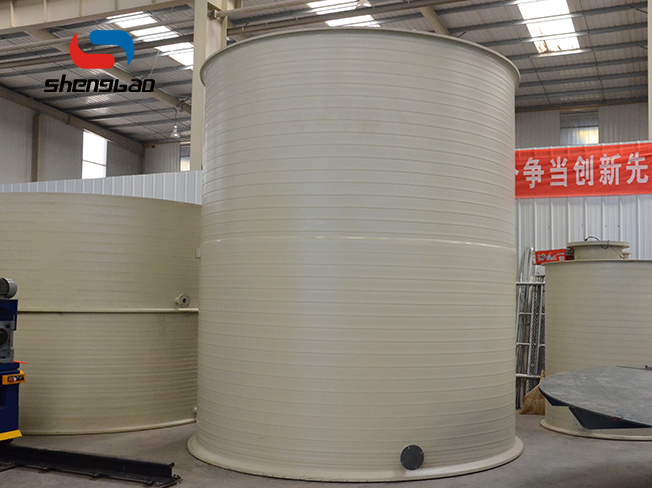

Method for extending the service life of plastic pp storage tank

- Time:2023-12-06

- Visits:111

Plastic pp storage tank is a container for storing and transporting substances, with excellent corrosion resistance, high strength and long service life, and its appearance can be made into a variety of vertical and horizontal. How to increase its use time?

1. The base request of the device plastic pp storage tank, and the platform level can accept the corresponding pressure. If it is made of steel, the gap should not be too large, and the board or iron plate should be laid. And the inspection board can have sharp objects like nails to avoid damaging the tank, and concrete can be used as a base.

2. When storing chemicals in plastic pp storage tank, after the storage tank arrives at the scene, there should be a good drainage tank and dilution device around the scene, or a leakage device.

3, like 20 cubic, 30 cubic and 50 cubic plastic pp storage tanks in the installation process, try to use a crane into the site.

4. After the installation of the plastic pp storage tank, the sealing performance of the interface should be stopped in time before use. If conditions permit, you can add liquid over the interface to see if there is a leak. It is recommended to use water for leakage test of storage tanks containing chemical liquids to avoid unnecessary human and financial losses caused by a large amount of liquid loss.

5. The pipe connected with the lower flange of the plastic pp storage tank should be perpendicular to the barrel wall. It is recommended to use a hose connection to avoid leakage caused by uneven shrinkage of the barrel wall after filling with liquid, damage to the connection flange, and directly affect the overall life of the barrel.

6. When the inlet is higher from the bottom of the tank, the inlet should be bent toward the wall of the tank, so that the incoming liquid falls along the wall of the tank to reduce the direct impact of the liquid on the bottom of the tank.